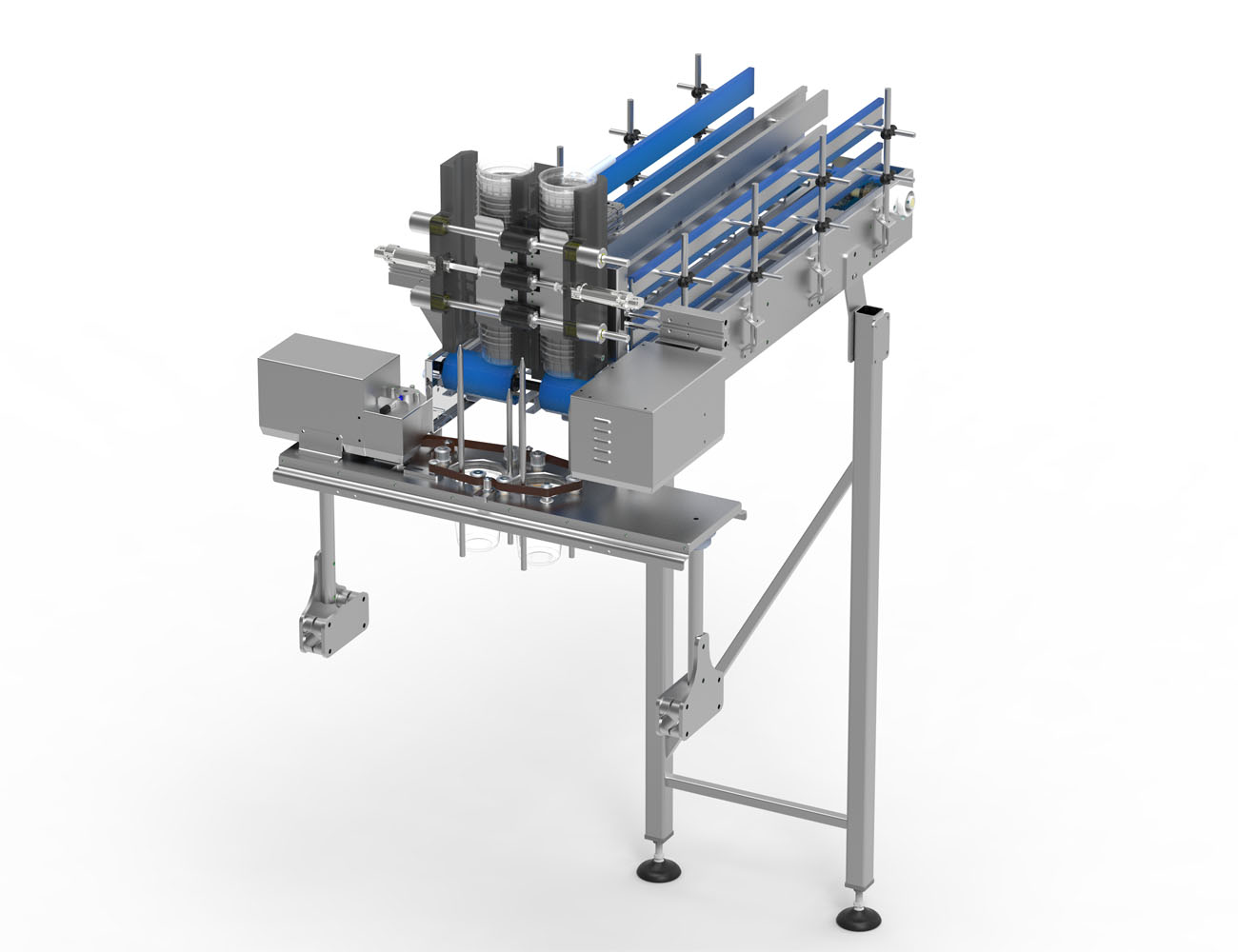

Cup In Feed Conveyor

The Principle Function:

The cups are fed as cup stacks on the “Cup In Feed Conveyor”. The cup conveyor is feeding the Cup Entering Station continuously with cup stacks. In this way the machine can run for up to 30 minutes without feeding new cup stacks.

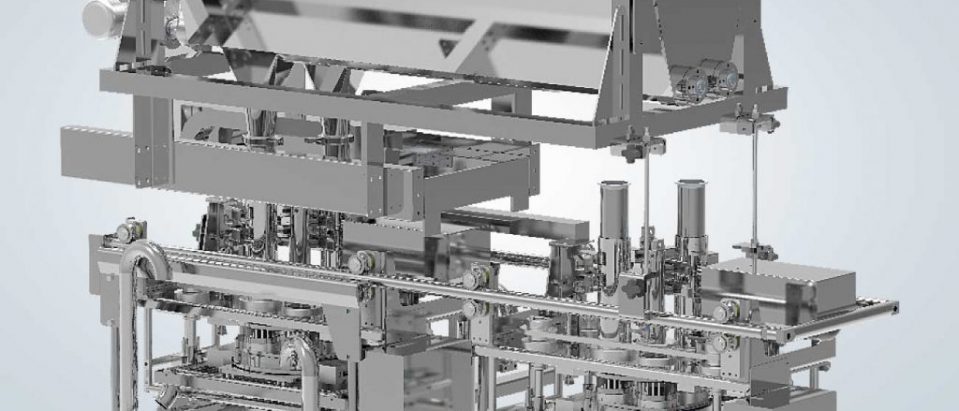

The Cup Exit Station brings out the cups from its undercarriage and transfers them to the conveyor.

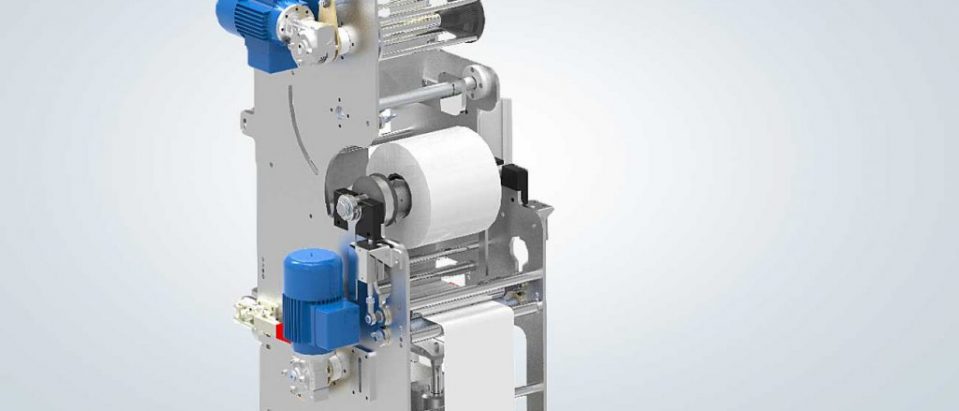

The Spice Dispersing Unit can put dry spices on top of the filled products, and the design of the spices on the product can be easily changed.

The Cup Entry Station is easily and quickly adaptable for different cup sizes. The station can be equipped with a cup sterilisation unit.

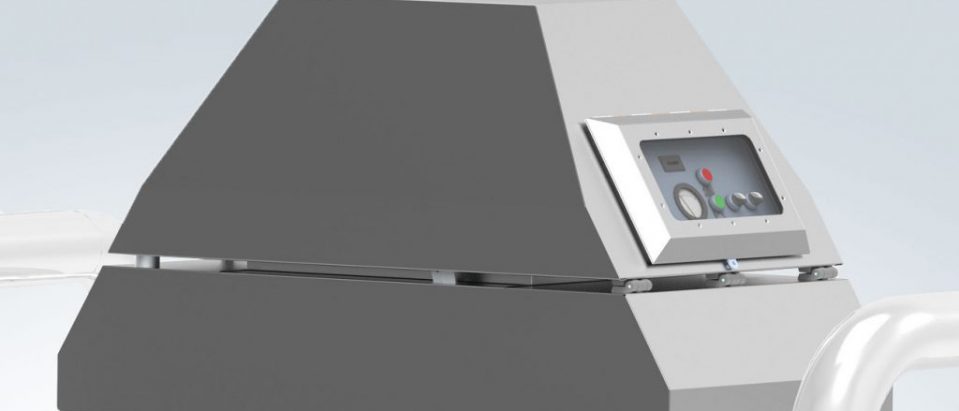

Clean air is necessary to fill products without preservatives. The filter housing of the unit is built from stainless steel and protects the filter from wash water.

The cups are fed as cup stacks on the “Cup In Feed Conveyor” allowing the machine to run up to 30 minutes without feeding new cup stacks.

The high clean filling nozzles for highly sensitive, highly hygienic products. Equipped with the “Seal Back Space Cleaning System”.

Fully automatic cleanable Salad Filling Station, for many different products like fruit salads, vegetable salads and more…

The Cup Sealing Unit seals the cups with foil. The complete unit is removable, without tools, for cleaning and maintaining.

The highly hygienic, servo driven dosing unit fills highly sensitive and viscose products and can be equipped with a pressure tank up to 2 bar.