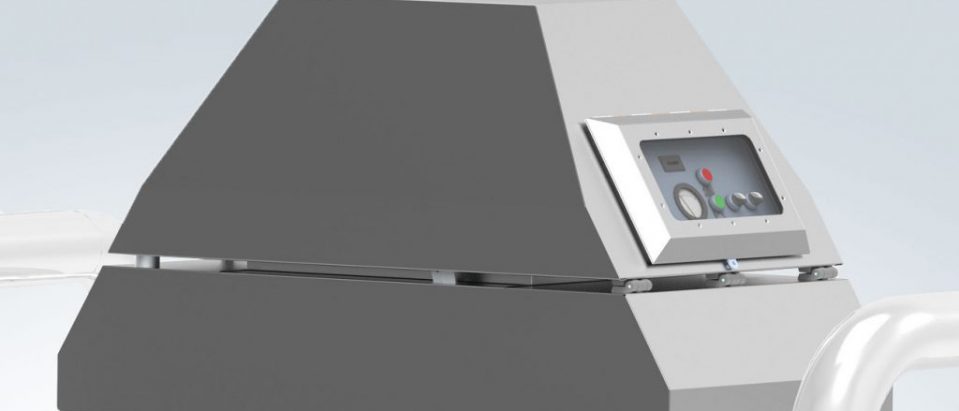

Cap / Lid Elevator

The Principle Function:

The Cap / Lid Elevator transports the lids into the cap orientation unit.

The elevator is available with two transportation conveyors for two different cap colors.

The Linear Bottle Accumulation Table can feed bottles to, or receive bottles from, the filler.

The Cap / Lid Elevator transports the lids into the cap orientation unit and is available with two transportation conveyors for two different cap colors.

Clean air is necessary to fill products without preservatives. The filter housing of the unit is built from stainless steel and protects the filter from wash water.

The high clean filling nozzles for highly sensitive, highly hygienic products. Equipped with the “Seal Back Space Cleaning System”.

The highly hygienic, servo driven dosing unit fills highly sensitive and viscose products and can be equipped with a pressure tank up to 2 bar.

The capping unit is built and designed to align, sterilise (optional), and screw the caps on to the bottles. The location of the caps is made with a round orientation unit or with an orientation conveyor. Sterilising the caps can be integrated into the cap slide, with ozone gas.

The cap screwing unit is made with a magnetic, torque-limited, gear motor, or with a servo-driven spindle. All the parameters are adjustable from the controller of the filling machine.

Conveyors connect the different machines / components.